- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

Shrink plastic film is widely used to package and protect various products. From food to electronics, it provides a secure seal, keeping items safe during transportation.

For DIYers or small-scale applications, you might wonder: Can a hair dryer be used to shrink plastic film?

In this article, we will explore how a hair dryer can be used, its limitations, and why professional tools are a better choice for high-quality shrink wrapping.

Shrink plastic films, such as PVC and POF, are designed with a "memory effect" that causes them to shrink when heated. As the film heats up, its molecular structure rearranges, allowing it to contract and conform tightly to the surface of the object it covers. This process is essential for protecting products by ensuring they are sealed properly.

When using a hair dryer to shrink plastic film, however, the heat distribution is not as controlled or focused as with other tools, such as heat guns. Hair dryers generally release heat over a wide area, meaning that certain areas of the film may shrink unevenly. This results in patches that may not shrink at all, leading to an inconsistent finish. This problem becomes more noticeable with thicker films, such as POF, which require a more concentrated and consistent heat source to shrink properly.

Hair dryers typically operate at temperatures ranging from 90°C to 150°C, which is enough to shrink thin films, such as those made from PVC. However, for thicker films like polyolefin (POF), this temperature range often isn’t high enough to achieve effective shrinkage. These films need temperatures that range from 120°C to 180°C to shrink properly, meaning that a hair dryer may not be sufficient for thicker or more durable materials.

In comparison, heat guns are specifically designed to reach higher temperatures, with more precise temperature control. They also focus the heat onto a specific area, which results in more uniform shrinkage. This makes heat guns a better option for most shrink film applications, particularly for those requiring a professional finish.

| Advantages of Using a Hair Dryer | Limitations of Using a Hair Dryer |

|---|---|

| Availability: Most households already have a hair dryer. | Uneven Shrinking: Hot air spreads across a wide area, causing inconsistent results. |

| Cost-effective: No need for additional investment if you already own a hair dryer. | Ineffective on Thicker Films: Hair dryers cannot reach the high temperatures needed for thicker films like polyolefin (POF). |

| Safety: Lower heat reduces the risk of damaging delicate items. | Limited Application: Not suitable for large-scale or professional shrink wrapping. |

One of the key advantages of using a hair dryer is its availability. Since most people have a hair dryer in their homes, it’s an accessible tool for small DIY projects. There's no need to purchase specialized equipment if the task at hand is minimal, such as wrapping a few small gifts or sealing minor imperfections in shrink-wrapped products.

A hair dryer can also be cost-effective. If you only need to shrink a few items, purchasing a heat gun or shrink tunnel might not be justified. For testing the process or handling small-scale tasks, a hair dryer can serve the purpose without the need for additional expenses.

Finally, a hair dryer is safer for delicate items. The relatively low temperatures used in hair dryers reduce the risk of overheating or damaging products, which is a common concern when using higher-heat tools such as heat guns. This makes it a better option for items that may be sensitive to extreme heat, such as electronics or fragile packaging.

Despite its advantages, a hair dryer has notable limitations. The most prominent issue is uneven shrinking. Hair dryers tend to blow hot air over a large area, which doesn’t allow for the focused application of heat that shrink films need. As a result, the shrinkage is often uneven, leaving wrinkles, bubbles, or areas where the film doesn't shrink at all.

In addition, thicker films, like POF, simply cannot be properly shrunk using a hair dryer. These materials need much higher temperatures to shrink effectively, which hair dryers cannot provide. For thicker shrink films, a heat gun or shrink tunnel is a better alternative.

Finally, the limited application of a hair dryer makes it unsuitable for professional or large-scale shrink wrapping needs. If you are working on multiple products or need consistent, professional results, using a hair dryer will not provide the level of quality or efficiency required.

A hair dryer may work well for small tasks or DIY projects. For example, if you have a few personal items to shrink wrap, like books or gift baskets, a hair dryer can perform the job adequately. It is also useful for fixing minor packaging issues, such as sealing the edges of a shrink-wrapped item that hasn’t fully sealed.

When working with lightweight shrink film materials or handling small products, a hair dryer is likely sufficient for the task. It can quickly seal products in a short time frame, but the finish may lack the professional look seen with commercial equipment.

In emergency situations where you don’t have access to a heat gun or shrink tunnel, a hair dryer can serve as a temporary solution. If you need to shrink a small item quickly or finish a last-minute project, a hair dryer can save time without the need for extra equipment. However, be prepared for uneven shrinkage, as the results may not be as polished or durable.

Heat guns are designed to shrink plastic films, providing more control and precision than a hair dryer. They deliver concentrated hot air, allowing you to focus on specific areas of the film that need shrinking. This ensures that the entire surface is evenly heated, preventing wrinkles and ensuring a consistent, tight shrink.

Heat guns are especially effective for thicker films, such as polyolefin, which require temperatures that a hair dryer cannot produce. These specialized tools also allow you to adjust temperature settings, providing greater flexibility for different shrink films and varying project needs.

For businesses or larger-scale operations, a shrink tunnel is the best choice for consistently applying shrink film. Unlike heat guns, which are handheld, a shrink tunnel provides continuous, automated shrinkage. This means that high volumes of products can be processed with consistent results and minimal hands-on effort.

A shrink tunnel also offers uniform heat distribution, which is essential for professional packaging. This results in high-quality shrink wrapping that minimizes the risk of errors, such as overheating or uneven shrinking.

When using a hair dryer for shrinking plastic film, it’s important to select the right type of film. Thinner films like PVC are more responsive to lower temperatures, making them easier to shrink with a hair dryer. Opt for flexible films to ensure that they shrink tightly without wrinkling.

Choosing the correct film is essential for achieving the best results. Thicker films like POF require a higher temperature than a hair dryer can provide and will not shrink properly, resulting in an uneven finish.

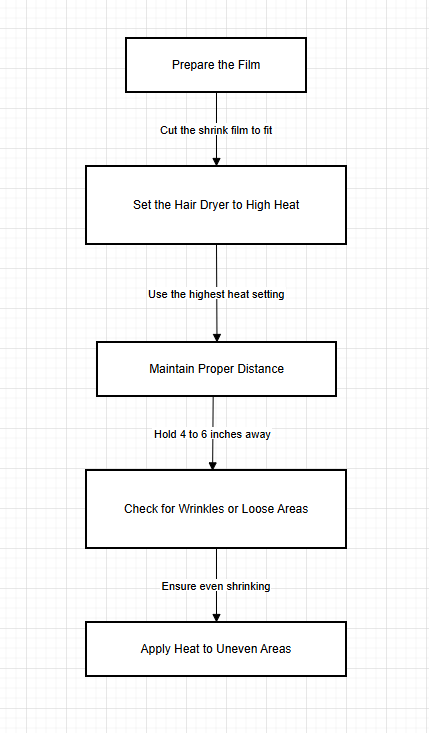

To get the most out of your hair dryer, follow these steps:

Prepare the Film: Cut the shrink film to fit the object you’re wrapping. Ensure it’s snug but not overly tight.

Set the Hair Dryer to High Heat: Use the highest heat setting on the hair dryer for the best chance of success.

Maintain Proper Distance: Hold the hair dryer 4 to 6 inches from the film and move it slowly across the surface. This ensures even heat distribution and reduces the risk of overheating any one spot.

Check for Wrinkles or Loose Areas: After a few moments, check to see if the film is shrinking evenly. Apply heat to any areas that aren’t shrinking properly.

By following these steps, you can improve the effectiveness of a hair dryer for small shrink film tasks. However, keep in mind that it still might not provide the same level of consistency as professional equipment.

While a hair dryer can be used for small projects or personal use, it’s important to consider upgrading to more professional tools if you frequently work with shrink films. Heat guns and shrink tunnels provide better control, precision, and efficiency, making them ideal for larger projects or businesses that require consistent results.

Investing in professional equipment can provide several key benefits:

Efficiency: Professional tools like heat guns and shrink tunnels reduce the time spent on shrink wrapping, allowing you to handle more products in less time.

Consistency: These tools offer more precise temperature control and focused airflow, ensuring consistent shrinkage and high-quality results every time.

Cost Savings: Although professional equipment comes with a higher initial cost, it reduces the likelihood of errors and waste, ultimately saving you money in the long run.

While a hair dryer can technically shrink plastic film, it is not the most effective or reliable tool for high-quality shrink wrapping. The limitations of a hair dryer, such as uneven heating, lower temperatures, and difficulty handling thicker films, make it less suitable for professional or large-scale applications.

For consistent and efficient shrink wrapping, investing in a heat gun or shrink tunnel is the best option. These tools offer better control, better results, and are specifically designed for shrink film applications, making them a valuable investment for businesses and professionals.

Yu Long Packing Co.,Ltd. offers high-quality shrink film solutions that provide better control and consistency. Their products ensure reliable, professional results for all shrink wrapping needs.

A: Yes, a hair dryer can shrink plastic film, but it may not provide the best results. The heat is not as concentrated, leading to uneven shrinking. For more consistent results, it's better to use a heat gun designed for shrink plastic film.

A: A heat gun offers higher temperatures and more focused airflow, ensuring even shrinkage of plastic film. Unlike a hair dryer, which spreads heat over a wide area, a heat gun concentrates heat on specific areas for better results.

A: No, hair dryers usually can't reach the high temperatures required for thicker shrink plastic films. For optimal results, it's recommended to use a heat gun or shrink tunnel for thicker materials.

A: Using a hair dryer can lead to uneven shrinkage and inconsistent results. The low heat and lack of control make it less ideal for achieving professional-quality shrink plastic film applications.

A: For small, simple projects, a hair dryer can be sufficient. It works best for thin shrink plastic films and small items, but for larger or more complex tasks, professional equipment like heat guns should be considered.