- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

Stretch film is an essential packaging material in many industries. It helps secure and protect goods during transportation and storage. The thickness of stretch film plays a crucial role in its strength and performance. In this article, we will discuss how stretch film thickness impacts packaging efficiency. You’ll learn how to select the right thickness for different applications and the factors that influence this choice.

Stretch film thickness is typically measured in microns (µm) or gauge, indicating the film's density and strength. A micron is one-millionth of a meter (0.001 mm), while a gauge is a measurement used to define thickness in the imperial system. Higher values indicate thicker film; for example, 100 gauge is thicker than 80 gauge. In most global markets, microns are the standard measurement, with a typical range for stretch film varying from 12 µm to 30 µm depending on the application.

Based on the specific needs of different applications, selecting the appropriate thickness ensures a balance between packaging effectiveness and cost. The table below breaks down the common stretch film thickness ranges, detailing the applications, technical specifications, and considerations.

| Thickness Range (µm) | Application | Technical Specifications | Benefits | Considerations |

|---|---|---|---|---|

| Light Duty (12-17 µm) | Small, lightweight products, general wrapping | Puncture Resistance: Low, Tear Resistance: Low | Cost-effective, easy to stretch, ideal for hand wrapping | Not suitable for heavy or sharp-edged items |

| Medium Duty (17-20 µm) | Standard pallets, moderately heavy products | Puncture Resistance: Moderate, Tear Resistance: Moderate | Good balance of strength and cost, versatile | Suitable for most general applications |

| Heavy Duty (22-30 µm) | Heavy, sharp-edged items, industrial goods | Puncture Resistance: High, Tear Resistance: High | Excellent protection against sharp edges, durable | Higher cost, not as flexible as lighter films |

Tip: When wrapping heavy or irregularly shaped items, consider using heavy-duty stretch film to ensure stability and prevent punctures. For general purposes, medium-duty films offer a good balance between cost and strength.

The thickness of stretch film directly affects its performance. Thicker films offer greater strength, durability, and puncture resistance, making them ideal for heavy or irregularly shaped items. On the other hand, thinner films provide flexibility and cost-efficiency, making them suitable for lighter loads. Choosing the appropriate thickness ensures that the film performs its protective function while balancing material cost and load stability.

Blown stretch film is produced by forcing air into molten resin, creating a bubble that is stretched and cooled. This type of film is known for its strength, puncture resistance, and ability to handle heavy and sharp-edged items. Blown stretch film is ideal for general industrial use and offers superior stretchability, making it suitable for wrapping products with irregular shapes.

Cast stretch film is made by extruding molten resin onto a chilled roller. It is known for its clarity and smooth surface, making it ideal for applications where visibility is important. Cast films are excellent for wrapping lightweight products and offer good stretchability, but they may not provide the same puncture resistance as blown films. They are commonly used for medium-duty applications where clarity and a smooth finish are desired.

Pre-stretched film is stretch film that has been pre-stretched during production, making it easier to apply during packaging. It offers high performance at lower thicknesses, reducing material usage and providing cost savings. Pre-stretched film is ideal for wrapping lightweight and uniform loads, as it provides excellent stretchability without the need for high tension during application.

True gauge stretch film refers to film that is manufactured to precise thickness measurements, ensuring uniformity and accuracy. This type of film is ideal for applications where consistent performance is essential, such as when wrapping products on automated machinery. The precise measurement guarantees that each roll of stretch film performs consistently and effectively across all packaging operations.

When selecting the appropriate stretch film thickness, several factors need to be considered, including the weight, size, and shape of the product. Heavier and irregularly shaped items require thicker films for adequate protection, while lighter loads can be secured with thinner films. Additionally, the type of stretch wrapping machine and the transportation conditions will influence the film thickness selection.

For light-duty applications, such as wrapping small boxes or lightweight goods, stretch films between 12-17 µm are commonly used. These films provide sufficient stretchability and cost-effectiveness without compromising protection. Ideal for general-purpose wrapping, they ensure that products remain secure without excessive film usage.

Stretch films with a thickness of 17-20 µm are used for medium-duty applications. These films are well-suited for standard-sized pallets and moderately heavy items. They strike a balance between strength and cost, offering sufficient protection against moisture, dust, and minor handling stress while being economical for larger loads.

For heavy-duty applications, stretch films between 22-30 µm provide the necessary puncture resistance and durability. These films are ideal for wrapping heavy pallets, sharp-edged items, or industrial loads. The added thickness ensures that the load remains stable during transport and storage, even when exposed to harsh handling or environmental conditions.

When maximum durability is required, especially for very heavy loads such as machinery, industrial equipment, or large construction materials, stretch films above 30 µm are recommended. These films offer the highest level of puncture and tear resistance, ensuring that the load remains secure and intact during rough handling and long-term storage.

Thicker stretch films offer superior puncture resistance, making them ideal for protecting sharp-edged or irregularly shaped items. They withstand higher levels of stress, preventing the film from tearing during transport or storage. The added durability ensures that the load remains secure throughout its journey, reducing the risk of product damage.

Stretchability is a key factor in ensuring that the film tightly secures the load. Thicker films, while providing increased strength, may have slightly lower stretchability compared to thinner films. However, with the right application technique, thicker films offer excellent load stability, preventing shifting or tipping during transportation. Properly applied stretch film helps absorb the impacts of bumps or sudden movements during transport.

The choice of stretch film thickness is also influenced by the environmental conditions in which the products are stored or transported. Thicker films provide better protection in environments with high humidity, temperature fluctuations, or other harsh conditions. Choosing the right film thickness ensures that the products remain secure and protected against external elements, maintaining their integrity during transit.

Choosing the correct thickness of stretch film helps balance protection with cost-efficiency. Thicker films offer greater protection, but they also come at a higher cost. By carefully selecting the appropriate thickness based on the load's needs, businesses can optimize their packaging processes and reduce waste. Evaluating cost per load instead of cost per roll allows for a more accurate assessment of overall savings.

Using thinner films can reduce material waste while still providing effective protection when stretched properly. Stretching films up to 400% with machines reduces the need for excessive material and ensures a tighter, more secure wrap. Proper machine use ensures that thinner films provide the same level of strength as thicker films, reducing both costs and waste.

Overwrapping—using too much stretch film—leads to unnecessary costs and material waste. On the other hand, underwrapping can result in insufficient protection, causing products to shift or even become damaged during transit. Ensuring that the correct amount of film is applied for each load, without overwrapping or underwrapping, is key to maintaining cost-efficiency.

Air freight is subject to more jostling and movement than other transportation methods, which can lead to increased stress on the wrapped goods. Therefore, thicker stretch film is necessary to provide the additional stability required to secure the load. For road transport, which generally offers a more stable environment, a thinner film may suffice.

| Transportation Method | Movement and Stress | Required Film Thickness | Why Thicker Film is Needed | Considerations |

|---|---|---|---|---|

| Air Freight | High movement and jostling, frequent vibration | Thicker stretch film (22-30 µm or higher) | To provide extra stability and prevent damage from constant movement | Requires film that can withstand stress from rapid movement and vibration |

| Road Transport | Relatively stable environment, less movement | Thinner stretch film (12-20 µm) | Less need for extra stability; standard film provides adequate protection | Ideal for standard loads that don’t experience extreme shaking or vibration |

Tip: For air freight, opting for thicker stretch film ensures that your goods remain secure despite the constant movement and air turbulence. For road transport, thinner film is often sufficient for lighter loads or stable packaging conditions.

Rail and sea transport are relatively stable modes of transport compared to air freight. These methods typically do not require as thick of a film, but consideration should still be given to load size and shape. Thicker films may still be necessary for heavy or irregularly shaped loads to ensure proper stability during transit.

Conditions in storage—such as temperature, humidity, and vibration—also impact the choice of film thickness. For long-term storage, thicker films provide added protection against environmental factors like moisture or dirt. In contrast, short-term storage or stable handling conditions may allow for thinner films to be used, balancing performance and cost.

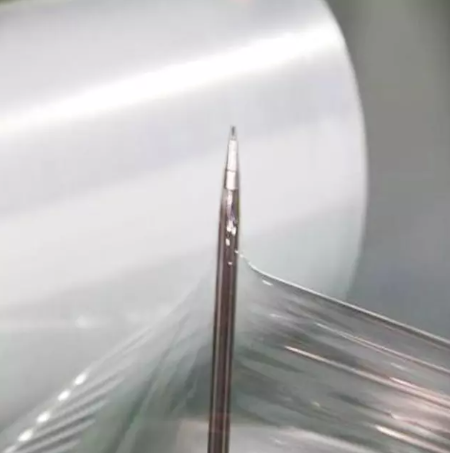

Stretch film thickness is typically measured using precise instruments like micrometers and digital calipers. Specialized gauges, including laser micrometers, offer high accuracy by detecting minute variations in thickness. To maintain uniformity, multiple measurements should be taken across different sections of the film, ensuring consistency. This is critical for maintaining the film's strength and performance. Automated systems are often used in industrial settings to guarantee reliable measurements and prevent human error during production.

To ensure the stretch film meets packaging requirements, comprehensive testing for tensile strength, puncture resistance, and stretchability is essential. Tensile strength ensures the film won’t tear under load, while puncture resistance tests its ability to withstand sharp edges or rough handling. Stretchability tests confirm that the film can extend properly without breaking, ensuring it securely holds the load. These tests simulate real-world transport conditions, ensuring the chosen thickness will perform optimally under stress.

Consistent thickness is vital for maintaining the structural integrity of stretch film during use. Variations in thickness can result in weak spots that may tear or fail under pressure, leading to damaged goods and increased costs. Quality control systems that monitor thickness uniformity are essential for ensuring film reliability. Regular inspection and quality checks help mitigate production defects, guaranteeing the film performs as expected and reduces waste. This consistency is particularly important when films are used in automated wrapping systems.

In conclusion, selecting the right stretch film thickness is crucial for ensuring the safe transport and storage of goods. By understanding how thickness impacts performance, businesses can optimize their packaging processes, improve cost-efficiency, and reduce waste. Choosing the correct thickness based on load size, weight, and transport conditions ensures better protection and reduced costs. Yu Long Packing Co., Ltd. offers a range of stretch films designed to meet diverse packaging needs, providing durability and value for businesses seeking reliable and cost-effective solutions.

A: Stretch film thickness refers to the film's density and strength, usually measured in microns (µm) or gauge. Thicker films provide more protection, while thinner films are cost-effective for lighter loads.

A: Choose the thickness based on your load’s weight and shape. Light-duty items require thinner films (12-17 µm), while heavy or sharp-edged items need thicker films (22-30 µm) for better protection.

A: The thickness of stretch film affects its strength, stretchability, and puncture resistance. Thicker films provide more durability, while thinner films offer flexibility and cost savings for lighter products.

A: Thicker stretch film provides better protection but is more expensive. For lighter loads, using thinner films is more cost-effective while still offering sufficient protection.